Lean Cash Management

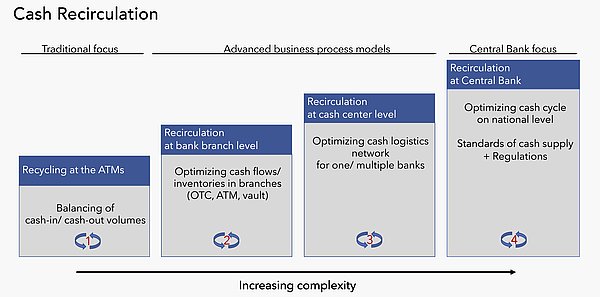

Permanent cost optimization throughout the cash cycle is a must in response to fluctuating cash volumes. The delegation of tasks by Central Banks to commercial players, and the closing of unprofitable sites by commercial banks will be not sufficient to reduce cost of cash in future. Continuous process improvement (CIP) of each cash cycle participant is necessary, and Lean Cash Logistics is the right tool.

The implementation of Lean Management in cash handling industry leads to cost savings of up to 35%, higher productivity per employee, minimal error rates and optimal cash inventories.

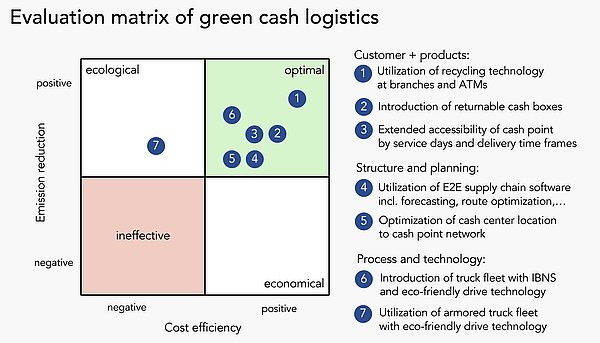

The volume fluctuations during the pandemic show how important a flexible and agile organization can be within the cash supply chain. Additional requirements towards green cash logistics, improved digitalization and automation are more achievable, if cost reductions through a Lean Program allow free cash flow for upcoming investments.

We work together with you to implement lean principles, identify waste in cash handling and organizational barriers along the cash supply chain. Important starting points for Lean Cash Logistics are:

- Standardization of cash boxes - utilization of returnable box systems for banknotes and coins reduces the variety of transport containers, cassettes, or sealbags. The consistent implementation of box identification and monitoring enables a precise attribution of cash articles to boxes. This shortens process times for handovers of cash shipments, for loading/unloading of CiT vehicles, and for cash storage/retrieval in the vault.

- Total Productive Maintenance - high system availability of cash center equipment, CiT vehicles and ATMs creates employee and customer satisfaction. Preventive maintenance and repair are just one part of the lean program to avoid downtime risks, quality losses and expensive ad hoc orders. The aim is to optimize the Overall Equipment Efficiency (OEE) of the cash infrastructure.

- Analysis of organizational interfaces – process disruptions and bottlenecks in cash handling or in the exchange of data along the supply chain leads to waiting times during cash handovers between transport and cash centers/ branches. Idle times at banknote/ coin processing systems reduce their productivity due to a lack of currency replenishment. Identifying and analyzing these weak points is an important tool for streamlining cash logistics.

- Kanban - order processing and control is based on the actual cash-in/ cash-out per location. The correct configuration of monitoring and forecasting software enables an optimized cash replenishment of ATMs and of branches. A Demand-Driven Cash Requirement Planning (DMRP) approach stabilizes fluctuations in cash orders and smooths order peaks along the supply chain with the effect of freeing up capacities in CiT transport and cash centers.

Services in Lean Cash Management

The program focuses on optimization of value stream throughout end-to-end cash supply chain. We utilize a combination of different principles.

- Value Stream Management - mapping of "as-is" material and information flow, design of "to-be" scenario, as well as planning and implementation of action plan

- Value proposition - resharpening of service portfolio regarding value for customers

- Lean cash order fulfillment - end-to-end process design from order placement to invoicing for regular, single and special orders

- Make or buy - defining efficient and robust outsourcing along cash supply chain

- Operational excellence - optimization of productivity and process quality in cash centers and transport (5S, zero-error concept, just-in-sequence, one-piece-flow, pull-principles/ Kanban, TPM)

- Automation of cash supply chain - digitalization of cash processes, integration of automation and logistics standards

- Knowhow transfer - on-site trainings/ workshops for implementation of continuous improvement process (CIP) across all organizational levels

Optimization of cash centers

- Cash box and cart concept - optimized cash transport and storage units for efficient operation of small lot sizes

- Workstation design - efficiency of currency prepping and processing, order picking and consignment, shipment handover at receiving and shipping bays

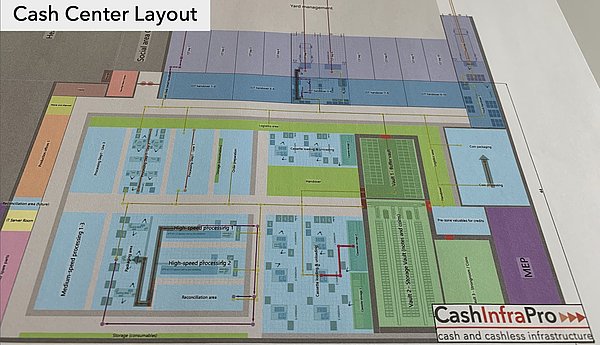

- Cash center layout - optimized material and information flow at and between working areas

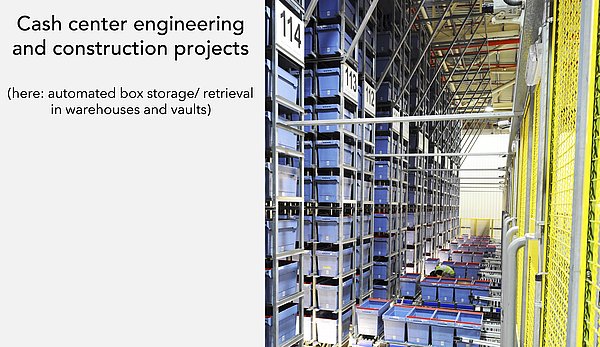

- Automation of storage and retrieval - faster stock turnover through inventory and replenishment control, ASRS/ robotic process automation

- System utilization - flexible organization of working area enables banknote/ coin processing without disruption/ idle times

- Total Productive Maintenance - increased system availability within cash center

- Cash center management software - correct information delivery to each workstation enables fast and accurate response

Optimization of cash supply chain

- Transport network planning - optimized route planning, IT software architecture

- ATM service and maintenance - organizational fit to end-to-end accountability for ATM up-time and lifetime costs

- Total Productive Maintenance - increased system availability of CiT vehicles and ATMs

- Decision support systems - dashboards with operational and logistical benchmarks (KPI)

- Risk management - integrated process reliability with tools for tracking & tracing and inventory control

Automation of banknote processing: