Cash Center systems often operate at less than full capacity, with low productivity and the cost of processing, storage and cash delivery are higher than originally planned. Total Productive Maintenance (TPM) programs have the aim to optimize availability, performance and quality level of cash center systems. They can be adapted for banknote and coin processing and packaging systems as well as automated storage and retrieval, preparation, IT and security systems. The essential benchmark figure is the Overall Equipment Effectiveness (OEE).

The success of automated cash handling processes depends on the efficiency of the selected and implemented systems over lifetime. Recent studies show that 25-30% of total cost for cash processing and packaging is attributed to maintenance activities in automated cash centers. The Productive Maintenance significantly affects business profitability. Surprisingly, cash center organizations accept average OEE rates of approx. 60%. World class OEE is considered to be 80% and better. Clearly, there is room for improvement in many organizations!

OEE improvement by TPM implementation

TPM concepts are long time proven and shows success in many highly automated industries. The principles can be adapted to cash handling systems. TPM aims to increase the effectiveness of existing equipment in a given situation by maintaining and operating the systems at optimal level. This assures a reduction of system’s life cycle cost and maximizing processing throughput per shift. To operate with highest performance, no disruption due to equipment breakdown, stoppages and failures/ rejects shall occur in each cash center area. The aim to eliminate or to reduce productivity losses involves every level and function in the cash center organization, from top executives to cash center operators.

Productive Maintenance programs focus on the following:

- Maximizing Overall Equipment Effectiveness

- Implementing concepts of preventive maintenance over system’s life span

- Involving all employees in the cash center organization

- Establishing autonomous maintenance by cash operators as team with technicians

- Ongoing analysis of productivity losses through integration of sensors/ software/ EDI to ensure fast and flexible reactiveness. Internet of Things (IoT) enables a integration of systems within a digitalized process flow.

- Continuous education and training for managers, technicians and operators

The activity list shows that closing a maintenance contract with suppliers will be only a first step to ensure system availability in general. TPM makes an impact on cooperation between cash center managers, technicians and operators. Major steps are an implementation of 5S principles in the operations, autonomous maintenance by operators with standards for cleaning, inspection and preventive maintenance for each machine type, analysis of abnormalities for each system supervised by technicians for further interaction. Overall, operators and technicians share responsibility for performance and health of their equipment.

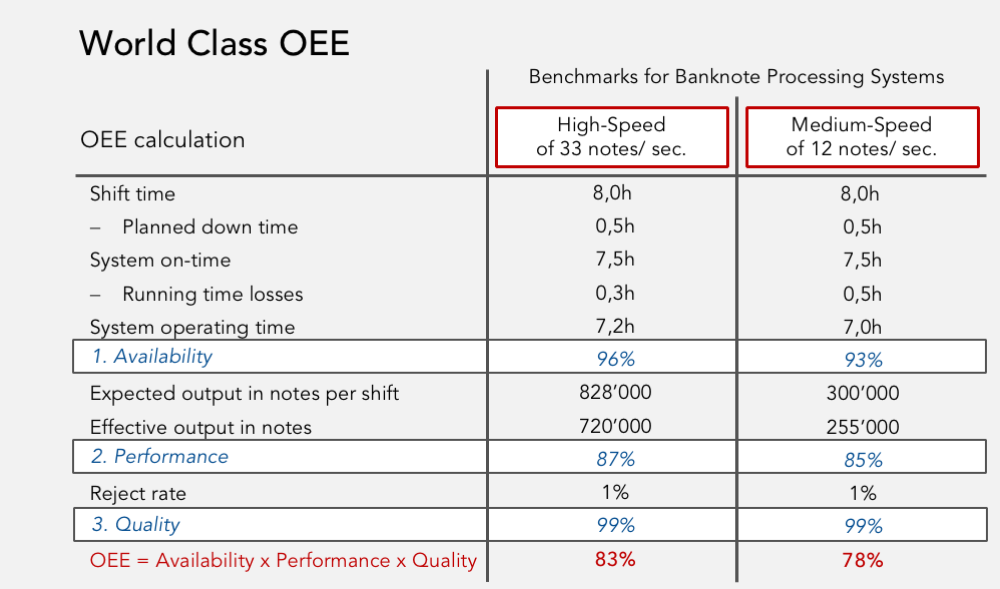

Benchmarks for Banknote Processing Systems

OEE measurement is an important way of analyzing the efficiency of a single machine or an integrated operation system. The example shows references for improved banknote processing systems for high and medium speed machines with 8 hours shift pattern. The OEE is based upon „system on-time“; the shift time reduced by planned down time, e.g. for machine inspection and cleaning per shift. Running time losses are caused by repairs during shifts or unplanned operational stops due to not available note volumes. This results in „system operating time“ and availability rate. The performance rate is the ratio between expected and effective output based on „system operating time“. The productivity losses are based on stops due to banknote jams or changing of consumables and other operational inefficiencies. From system sensors rejected notes are allocated in the quality rate. OEE is a function of system availability, performance and quality/ reject rate. [compare picture]

Conclusion

Modernization favorites enhanced process automation and operational concepts to reach optimal OEE levels for each cash center area. TPM is an essential concept that makes the difference between success and failure of investments. It has been proven to be a program that works in many industries and can be adapted for cash cycle optimization as well. The results show capabilities to improve effectiveness and profitability in cash center, CiT and ATM business by more than 20%.

Do you want to know more about improved OEE by TPM implementation, please contact us.

Sources: Cash InfraPro analysis and performance programs for cash cycle optimization