Risk Management for cash supply chains shall assure secure and efficient processes. Ink-dye technology is a smart alternative to protect cash inventories and transport of cash instead of armoring and weapons. The implementation of ink technology systems will be a step forward to optimize cost of cash handling in more and more countries. The additional investment in ATM technology is justifyable as banks/IAD`s will redically reduce the risk of physical and gas attacks against ATMs. Improved cash logistics based on soft-skin vehicles with ink protection will increase profitability of CIT companies as well. The results are outlined in the latest feasibility studies.

Ink technology as future standard

Ink staining of banknotes is an accepted standard to protect cash inventories against criminal acts in many European countries. IBNS (Intelligent Banknote Neutralization System) technology activates ink staining of banknotes, if an unauthorized access to cash is detected. If banknotes inside ATM vaults or transport cassettes are protected with ink-dye, criminals will think twice before taking the risk. Sweden and Belgium introduced ink-dye protection beginning of this century with striking success. The unedifying growth in physical and explosive attacks towards ATMs and armored trucks was significantly reduced. Similar experiences were reported from France and Chile after the introduction of the IBNS technology.

So why are banks and CiTs so reluctant to implement ink technology?

Ink technology for ATM inventories

In Germany, ATM gas attacks are on a raise from 38 in 2011 to 89 in 2013, peaking at 132 attacks in 2015! But instead of investing in new ink technology the banks rather close ATM locations over night and accept to ruffle feathers of their customers. The investment cost into ink technology is apparently the prime reason of banks to lose sight of the risk and possible cost implications of a potential attack. Recent studies outline a monetary damage of $63’000 (international average) caused by an attack with explosives considering the collateral, but not the image damage for the bank. In Germany as of the higher cash inventories the monetary damage is reaching an average between 70’000€ and 90’000€.

A feasibility study of Cash InfraPro for Mexico comes to the result, that banks can improve their security in ATM locations by introducing IBNS technique. Even an investment in IBNS technology by only 25% of the locations - focussed on high risk areas - will result in a drop of attacks by 75% within next 18 months. Similar experiences are reported from Sweden and Chile. Translating these facts for a bank with an installed base of approx. 6’000 units, ATM attacks can be reduced from todays 400 to 50 per year resulting into a saving potential of $25MM for next two years. In consequence an investment in IBNS technology will amortize in 6 months considering initial investments, on-site installation cost as well as the maintenance of ink equipment during its lifespan, training of staff and adequate project management for planning and implementation. Overall a lucrative investment.

Ink technology for cash logistics

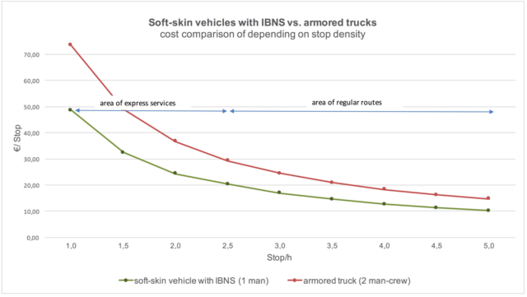

CiT companies are constantly challenged by customers to take over full liability for transport and cash processing for a competitive price. On the other hand risk management means to implement best practices to avoid external attacks and eliminating internal losses. The success of ink technology in “high risk” countries initiated a debate about the pros and cons of the IBNS technique vs. armored trucks plus weapons for the personnel. The main argument is that the investment for organizational reengineering overburdens the financial strengths of CiTs, which have no longtime commitment from their customer base. In addition the CiTs are struggling with the quality of installed ink systems, which shows a high failure rate in the past. This results in a trust-less commitment of CiT organizations for IBNS technology, even if a business case is feasible.

But CiTs neglect the competitive advantage of the latest IBNS generation. Swiss based company VILLIGER is leading todays quality benchmarks for IBNS technology. With continuous development of modular IBNS equipment with outstanding reliability and robustness in day to day operation, VILLIGER is able to bring failure rates in operation constantly below 1% p.a. Compared to the reported rates of more than 9% in Belgium a tremendous improvement with positive impact to Total Cost of Ownership (TCO) and Return of Investment (ROI) for VILLIGER customers, beside a lifetime warranty on the ink staining equipment. The transformation from “armored transport” to “soft-skin vehicles with IBNS” can get concluded and is feasible for developed as well as for emerging markets.